The main alloying element of 7075 is zinc, and magnesium can also be added to form an alloy with a significant strengthening effect. After heat treatment, the alloy can achieve very high strength. In this series of alloys, 7075-T651 is a very high-quality alloy with high strength, good mechanical properties and anodic reaction.

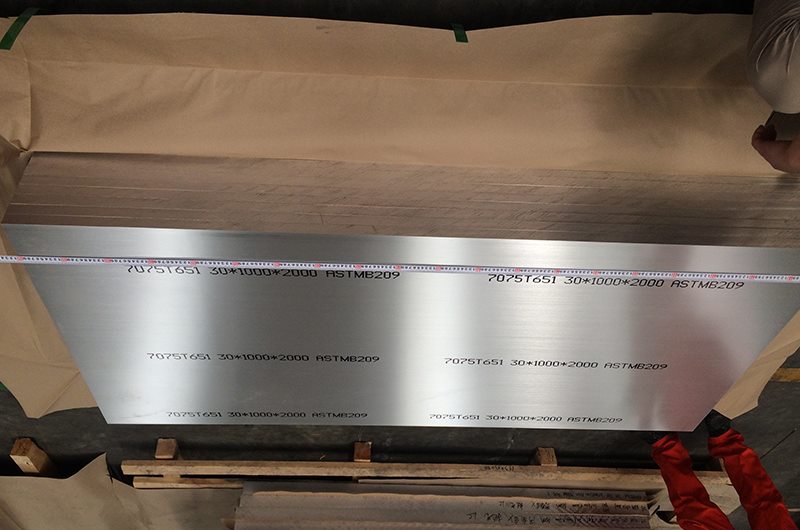

Size:

Alloy:7075

Tmeper: T651

Thickness: 1MM-400MM thick

Width: 1250*2500 ,1520*3660

7075 T651 Aluminium rectangular bar belongs to Al-Zn-Mg-Cu super-hard aluminum. The plasticity of 7075 in the annealed and as-quenched state is slightly lower than that of 2A12 in the same state. It is slightly better than 7A04. The static fatigue of the plate is sensitive to notches and has excellent stress corrosion performance. In 7A04, 7075-T651 is particularly top-grade, and it is known as the most excellent product among aluminum alloys, with high strength and far better than mild steel. This alloy has good mechanical properties and anode reaction, and is a typical aerospace aluminum alloy material.

7075 T651 Aluminium rectangular bar

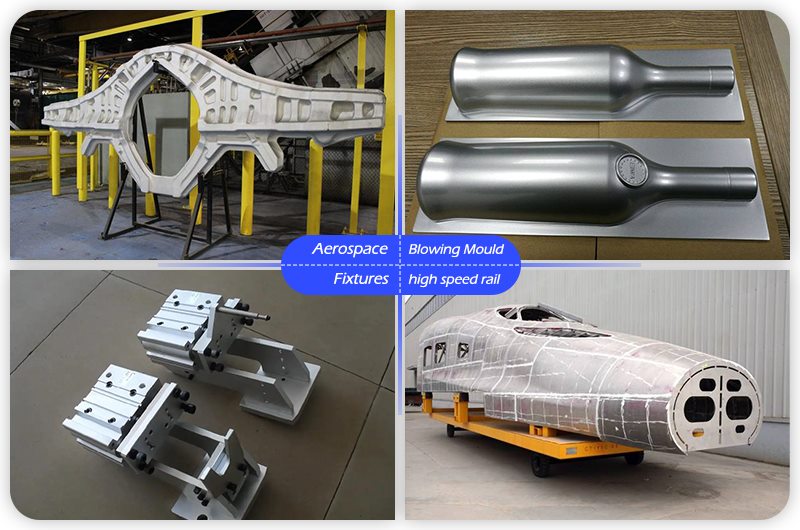

Applicable to: aerospace, mold processing (such as foaming molds, blowing molds), mechanical equipment, tooling fixtures, high-speed rail, semiconductor equipment, etc.. Especially used for the manufacture of aircraft structures and other high stresses that require high strength and corrosion resistance structure.

7075 T651 Aluminium rectangular bar has the following characteristics:

1. Good material density: the unique grain refinement process guarantees that there are no sand holes, horizontal lines, bubbles and impurities;

2. High surface accuracy, reducing material waste

4. Good processing performance: reduce the deviation of chemical composition, strength and hardness to a small amount, and prevent the phenomenon of "sticking knife" and "knife breaking" during processing;

3. High-speed machining, almost no deformation: The pre-stretching (T651) process treatment completely eliminates internal stress and is not easy to warp, crack and deform during processing and stress;

5. High temperature resistance: no deformation under 400℃ working environment;

6. Good uniformity of material: excellent heat treatment technology, the strength and hardness of the product are basically the same when the thickness (diameter) is below 300℃;

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic).whether you are inquiring about the latest quotation of aluminum bars , or have any questions about aluminum rods, you can contact us ,our professional team will reply to you within one business day. Please feel free to contact us!

What is the 6063 t6 aluminum bar

6063 t6 aluminum bar containing magnesium, silicon, with excellent processin...+ Details

How can aluminum round bars be treated for anticorrosion?

The corrosion behavior of 6063 aluminum round bar caused by silicon can be c...+ Details

How much is a ton of aluminum bar?

Aluminum bars have a wide range of applications and many industries are inse...+ Details